In areas occasionally affected by hurricanes, light poles should have wind ratings designed to withstand wind speeds up to 150 mph – or the equivalent of a category 4 or 5 hurricane. More specifically, Effective Projected Area (EPA) wind ratings should be considered for areas that receive high winds.

Wind ratings describe the maximum wind speeds that a particular lighting fixture should be able to sustain before risk of failure. For light poles installed in areas affected by hurricanes, durable construction and clever fixture design are essential to mitigating failure with intense wind speeds.

How is a Light Pole’s Wind Rating Determined?

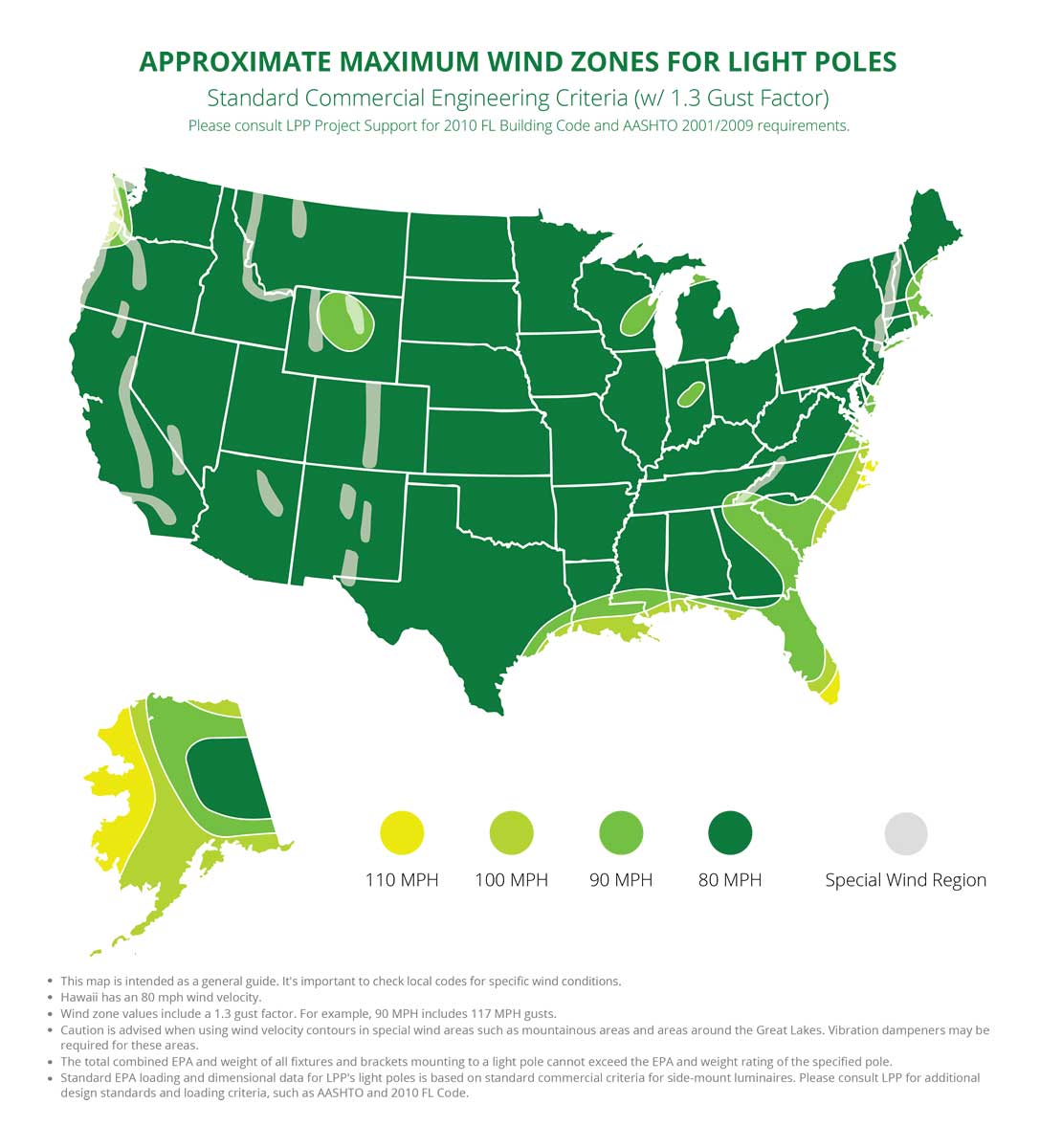

Lighting poles are responsible for bearing heavy loads without failing, around the calendar and in all weather conditions. One of the most challenging conditions for light poles is extreme wind. Wind-related stresses are present all along coastal areas, and special wind zones are also located in spots around the country, such as around mountain ranges, but hurricane zones require the greatest wind tolerances.

Wind ratings can be difficult to derive, as they rely on calculating the effective projected area (EPA) of the light pole and its fixtures. Think of it as the total area of all wind-exposed surfaces on the light pole and fixture. The light’s EPA value is multiplied by a drag coefficient to determine the pole and fixture’s wind rating. EPA values have been calculated by lighting manufacturers and the data is available to lighting installers, but as wind ratings depend on every component involved, wind ratings will change if different poles, fixtures, lamp housings or other accessories are switched out for each other. This can make precise wind rating calculations difficult without expert assistance.

How are Light Poles Fortified for Areas Affected by Hurricanes?

EPA wind rated light poles are constructed from solid steel or fiberglass materials – both of which are designed to hold up better under intense winds. These lighting poles are typically installed into concrete bases or footings to enhance their structural strength. The fixture is secured using high-strength brackets that are designed to bear additional loading forces.

Regular inspections and maintenance are important to ensure your EPA appropriate light poles can withstand heavy storms. When inspecting the light poles and fixtures, verify that corrosion or impact damage are not present and threatening the lighting pole’s stability. The concrete bases of the poles should also be inspected for damage or wear. Large cracks or fractures in the concrete or significant loss of aggregate merit an expert inspection to ensure the lighting pole is still properly anchored.

The Benefits of Installing Wind-Resistant Lighting Poles and Fixtures

Wind-resistant lighting poles are a necessary solution in areas where hurricanes are a potential threat as they provide additional benefits that include:

- Better overall safety – Lighting poles rated for hurricane-force winds are designed to withstand more than the typical light pole. As such, they are better designed to withstand high wind, wear and potential accidents. Reinforced bracketing and pole materials ensure that your lighting poles are less likely to fail and put nearby people and vehicles at risk.

- Greater load bearing capacity – Wind-resistant lighting poles are built to withstand greater forces and loads, including those caused by weight bearing. With their additional structural reinforcement and added ability to bear weight, EPA appropriate light poles may be able to accommodate larger fixtures or additional lighting accessories, such as lighting controls.

- Longer lasting investment – With their superior durability, structural integrity and wind resistance, property owners can expect their EPA wind rated light poles to last longer and provide additional long-term value.

The Advantages of Partnering with a Lighting Expert When Installing Lighting Poles in Hurricane Prone Areas

When installing lighting poles and fixtures in areas affected by hurricanes, it is highly recommended that an experienced lighting company manage the fixture selection and installation process, and here are the reasons why:

- Accurate wind ratings – As mentioned, it is a challenge for inexperienced installers to properly calculate wind ratings for a particular fixture arrangement. It is a risk not worth taking for business and property owners, and bringing in the lighting professionals eliminates that risk.

- Optimal fixture selection and placement – The lighting professionals utilize sophisticated photometric software to determine ideal pole placement and light selection. With photometric software, lighting designers can precisely place and configure pole and fixture placement. Photometric software uses lighting data and a computerized model of the project space to indicate the best possible lighting layout – from an energy efficiency and performance standpoint.

- A solution-based mindset – If your organization partners with an experienced lighting company, you will have access to expert insight that can provide long-range input into your lighting needs. If your property needs to cut its power consumption, for example, a lighting company can introduce additional lighting products and technologies (such as advanced lighting controls) to further your goals. There are many ways to adjust lighting systems to achieve desired facility-wide or business objectives. An experienced lighting company will be able to introduce these options and execute them for clients.

In Areas Affected by Hurricanes, Lighting Poles Must be Prepared for Intense Wind Speeds

If your property sits in an area where hurricanes are a possibility, your lighting poles’ wind ratings must be prepared for extreme wind conditions. This means wind ratings up to 150 mph, which can only be achieved if the right lighting pole materials and installation techniques are observed.

A reputable lighting expert will guarantee that your lighting fixtures are prepared for catastrophic weather and will also ensure they are placed and configured to offer optimal efficiency and lightning performance.

The EPA wind rating of a light fixture refers to the maximum wind speed the fixture can withstand before it is at risk of failure. This failure could be with the luminaire itself, or a failure with the fixture or the hardware connecting it to a light pole.

The EPA wind rating of a light fixture refers to the maximum wind speed the fixture can withstand before it is at risk of failure. This failure could be with the luminaire itself, or a failure with the fixture or the hardware connecting it to a light pole.